Customized Conversion Services

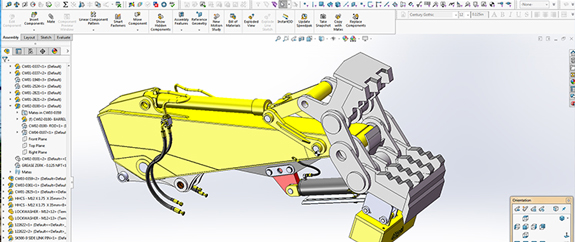

Company Wrench is responsible for the custom manufacturing and development of high reach excavators, long reach excavators. material handler conversions, and hybridizations. Our engineering and fabrication department has the experience, the latest in CAD software and a 15,000 sq. Ft. fabrication shop to provide the best conversion services in the industry. Our customized Conversions include Boom Conversions, Stick Conversions, Thumb Conversions, Additional Counterweights, Deep Dredging Conversions, Material Handling, Hybridizations, High Reach and Long Reach.

Here’s What Our Customers Say

“Company Wrench customized a Komatsu 450 and Hydraulic Thumb attachment for us and it has worked out great. By adding two teeth to the thumb,Company Wrench’s conversion allows us to grab rocks averaging 8-12 tons apiece more securely and maneuver them easily without slipping out of its grasp” — Justin with Meadville Land Service, a Pennsylvania company specializing in stream restoration.

See the hydraulic thumb in action

High Reach Conversions

High Reach Machines offer a safe option for the demolition of taller structures and are an economical and faster alternative in completing projects.

High Reach Conversions are available on all excavators.

Conversion options consist of:

- Two piece booms ranging from 50 ft to 65 ft

- Three piece booms ranging from 70 ft to 130 ft

- Full hydraulic plumbing

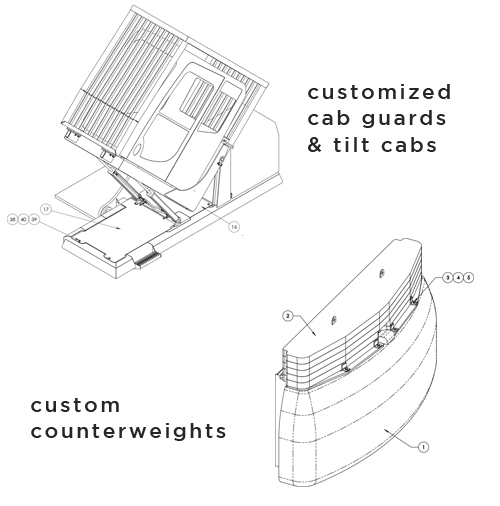

- 45 Degree Tilt cab

- Cab guards

- Counter weight

- Boom cradles for transportation

- Track widening as needed. Size appropriate per machine.

The entire high reach conversion process averages 5 to 8 months depending on the specifics of the project. The high reach conversion process consists of the following steps; blue prints drafted, boom assembly and counter weight fabrication, plumbing kit installation, painting of the entire machine and custom cradle design and build.

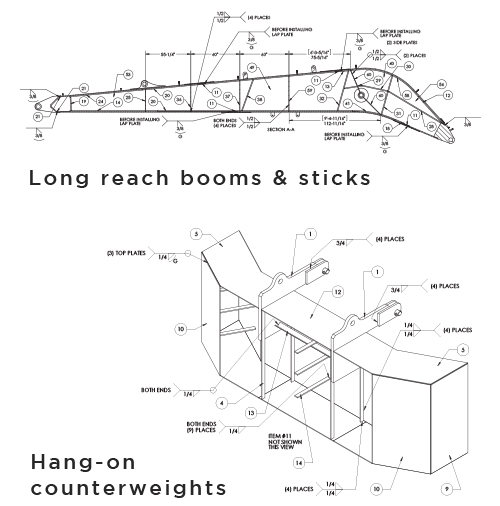

Long Reach Conversions

Long Reach Machines extend the work area over traditional excavators. Long reach machines have become the accepted standard for pond dipping and excavating hard to reach areas.

Long Reach Conversions are available for all excavator sizes and types. Booms and sticks can be modified to meet your specifications. If needed, additional counter weight is also available.

The entire conversion process averages 1 to 3 months depending on the specifics of each project. The overall process consists of drafting blue prints, cutting stick and/or boom, fabricating new sections, welding new sections into place, sanding and painting the boom and/ or stick to match the excavator.

Conversion options consist of:

- Custom booms & sticks with reach from 50 ft to 80 ft

- Full hydraulic plumbing

- Counter weight

- Boom cradles for transportation

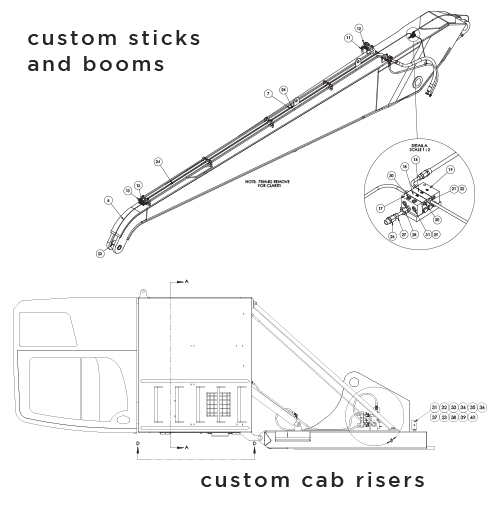

Material Handler Conversions

Material Handlers provide an efficient option for transferring material with grapples and magnets for the Material Handling Industry. Some of these industries include Inland rivers, ports and terminals, rail roads, coal handling, scrap handling and more.

Depending on your industry we have the right attachment for any and all material handlers. We have clam shell buckets, orange peel grapples, and magnets from the top manufactures in the industry.

Material Handler Conversions are available on all excavators. Conversion options consist of:

- Three cab riser options

- fixed riser/manual tilt

- fixed riser/hydraulic tilt

- hydraulic elevating cab

- 10kW to 30kW generators for magnet applications

- Grapple hydraulics

- Cab guards

- Counter weight

- Track widening as needed. Size appropriate per machine.

Make Company Wrench your first choice for material handling conversions and attachments.

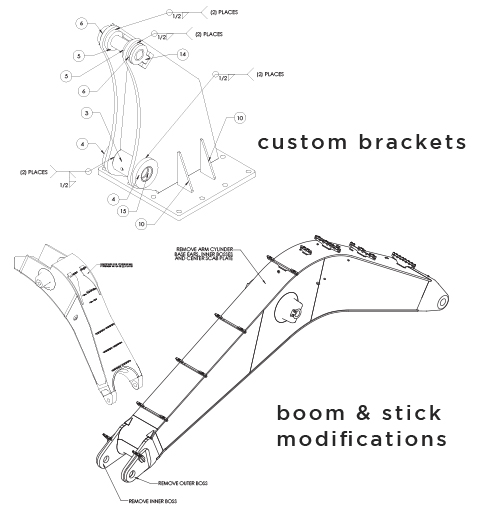

Hybridizations

With the right size attachment and a smaller machine, you get more work done while using less fuel, which means more money saved. We can also custom fit booms and sticks to suit many different machines. For example, our customer Sunshine Recycling had a Fuchs MHL360, but not with the right stick for a shear attachment. They needed the shear and the rubber tires, so dirt would not fly all over their lot. We transformed their Fuchs material handler into a custom hybrid shear machine. We can also change attachments, so they become more versatile, like the CP100 magnet combo. We designed and patented this attachment to crush concrete and removing rebar and precious metal without having to switch out attachments or use two machines.

Engineering Department

Company Wrench’s Engineering Department designs, engineers, and manufacturers top quality attachments, conversions and hybridizations for heavy equipment. We have the experience, the latest in CAD software and a 15,000 sqft. fabrication shop to provide the best conversion services in the industry.

Company Wrench employs Licensed Professional Engineers and a team of certified welders with an extensive knowledge of conversions to make the process consistent and timely.