Benefits of Heavy Equipment Maintenance Plans

Maintenance is the largest hidden cost associated with owning heavy equipment. Customers’ operating expenses are always rising due to increased parts prices and service rates. However, some equipment dealers offer a solution in the form of heavy equipment maintenance plans, which provide customers with discounted OEM parts, labor, and travel at a fixed rate over the duration of the plan. In addition to controlling operating costs, maintenance plans offer a number of other benefits.

Warranty Compliance

Nearly all heavy equipment comes with a manufacturer’s warranty. The manufacturer’s warranty can be limited in scope because it only covers certain components for an initial period of time (i.e. 2 years or 2,000 hours). Customers must follow the manufacturer’s operation and maintenance guidelines or their warranty may be voided, leaving them with large repair bills that may have otherwise been covered.

The right heavy equipment maintenance plan helps customers stay warranty compliant by ensuring factory-certified technicians service their machine at manufacturer-recommended intervals with OEM parts. This also helps minimize the need to file a warranty claim because many of these issues could be addressed before they become significant problems.

Increased Uptime and Longer Equipment Lifespan

Heavy equipment maintenance programs detect problems before they result in significant damage. Company Wrench offers a 53-point inspection during every service, which gives customers a detailed report on the status of their equipment. This allows customers to ask questions about potential repairs and best operating practices. In addition to informing customers about immediate repairs, maintenance plans also allow customers to have a forecast of potential future repairs and plan accordingly.

Higher Resale Value

Customers can expect higher resale value on their equipment if they invest in a maintenance plan. In most situations, the equipment will be in better condition compared to a machine that was not regularly serviced. Furthermore, customers can provide any prospective buyers with thorough documentation about the machine’s maintenance history.

“We believe that if we perform regularly scheduled maintenance on a customer’s machine, we can guarantee them additional trade value,” Company Wrench Product Support Sales Manager Drew Martin said. “Our maintenance plans include detailed notes from manufacturer-certified technicians who can explain the service performed on your equipment at key points of its lifespan. This helps customers have a better idea of their machine’s health, expected lifespan, and when it may need to be replaced.”

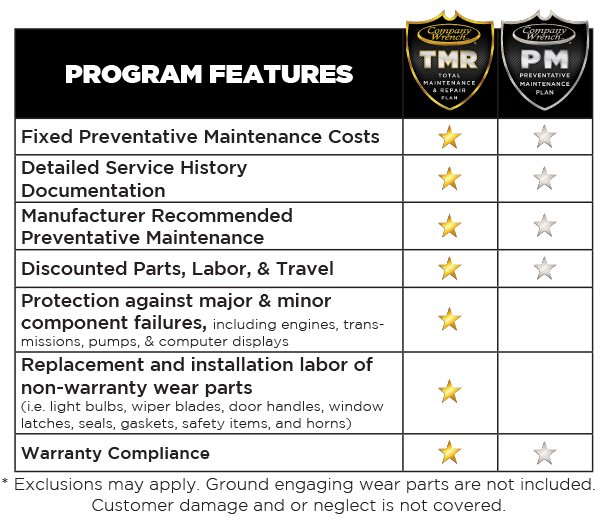

Company Wrench Maintenance Plans

Company Wrench offers three different maintenance programs: Preventative Maintenance (PM), Wrench Care, and Total Maintenance & Repair (TMR).

- PM: Customers who choose the PM plan will enjoy the benefits of a 53-point inspection during every service, as well as discounted OEM parts, labor, and travel at a fixed rate over the duration of the plan. This maintenance program allows customers to save costs associated with preventative maintenance services and identifies potential component failures before they become large repair bills.

- Wrench Care: This plan offers a more cost-effective alternative for customers who want the same great benefits as the PM plan on a smaller machine. Wrench Care covers the first 24 months or up to 1,000 hours of preventative maintenance on qualifying new Kobelco and JCB machines purchased from Company Wrench.

- TMR: This plan covers most wear items on the machine, and it gives customers protection against both minor and major component failures after the manufacturer’s warranty expires. This plan is designed for customers who want a full-service maintenance plan with 100% fixed maintenance costs.

Building a Maintenance Plan

Customers can customize a Company Wrench maintenance plan to control costs associated with parts, labor, and travel, resulting in large savings.

“We give customers a lot of freedom when creating their maintenance plan,” Martin said. “We start by asking customers for their equipment’s estimated annual operating hours. This allows us to communicate when they can expect key service points in their machine’s lifespan. From there, we can talk about the type of coverage they want and the savings they will see from locked in parts pricing, discounted labor rates, and reduced travel charges for the life of the contract.”

Contact Company Wrench for a free consultation where we can analyze your maintenance bills and compare them to the savings you could receive with a tailor-made maintenance plan.